Analysis of PCB Test and Specifications

In today’s rapidly advancing technological landscape, the reliability and functionality of printed circuit boards (PCBs) are crucial. To ensure their quality, pcb testing plays a vital role in identifying any potential defects or malfunctions. This article will delve into the significance of PCB functional testing, explore different types of tests conducted on PCBs, and discuss the advancements made by JinHua in this field.

The Importance of PCB Functional Testing

pcb functional testing is an essential step in the manufacturing process as it verifies whether a board meets its intended design specifications and performs as expected. By subjecting the board to various simulated scenarios and analyzing its responses, engineers can identify any flaws or weaknesses that may affect its performance.

This type of testing ensures that all components on the board are correctly connected, functioning properly, and interacting seamlessly with each other. It helps detect issues such as short circuits, open circuits, incorrect component values or placements, faulty connections, power supply problems, signal integrity issues, among others.

Different Types of PCB Tests

There are several types of tests performed during the evaluation process for ensuring optimal functionality:

- In-Circuit Testing: This test involves checking individual components’ electrical characteristics while they are still mounted on the board. It helps identify defective parts or solder joints.

- Flying Probe Testing: Utilizing automated probes to make contact with specific points on a circuit board without requiring a dedicated test fixture. This method is suitable for low-volume production runs due to its flexibility but may be time-consuming for large-scale production.

- Burn-In Testing: Subjecting fully assembled boards to elevated temperatures over an extended period simulates the stress they may experience during their operational lifespan. This test helps identify any latent defects that might arise under normal operating conditions.

- Environmental Testing: Evaluating PCBs’ performance under extreme environmental conditions, such as temperature variations, humidity, vibration, and shock. This ensures their reliability in real-world scenarios.

JinHua’s Advancements in PCB Testing

JinHua has emerged as a leading innovator in the field of PCB testing. Their state-of-the-art facilities and cutting-edge technologies enable them to conduct comprehensive tests with utmost precision and efficiency.

With an extensive range of advanced equipment and highly skilled engineers, JinHua specializes in developing customized testing solutions tailored to meet specific customer requirements. They have implemented automated testing processes that significantly reduce human error while improving overall productivity.

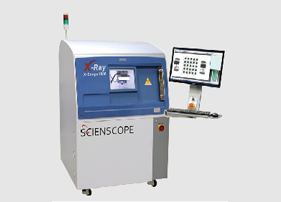

In addition to traditional functional tests, JinHua also focuses on implementing advanced techniques like X-ray inspection for detecting hidden defects within complex multilayer boards or BGA components. These advancements ensure higher quality standards and increased reliability of the final product.

Conclusion

In conclusion, PCB functional testing is crucial for ensuring the reliability and functionality of printed circuit boards. By conducting various types of tests throughout the manufacturing process, potential issues can be identified early on and rectified promptly. With companies like JinHua pushing boundaries through technological advancements in this field, we can expect even more precise and efficient PCB testing methods in the future.